Our first design for the structure called for 2″ diameter bamboo poles arranged in a helix pattern to form a 14 ft. hyperboloid tower. Each pole was going to be made up of two 8ft. pieces of bamboo cane coupled by using a two-foot 1″ round dowel inserted parallel through the middle of the cane. This would be secured by a 1″ inch cross-dowel pin in each of the two bamboo canes. We had to scrap that design because the bamboo was going to cost over $1200 before we even go to the doweling. Plus, Home Depot was out of stock of the product for several weeks following the the decision.

The solution that we came up with was lodge poles, such as those used to support tree saplings in landscaping.

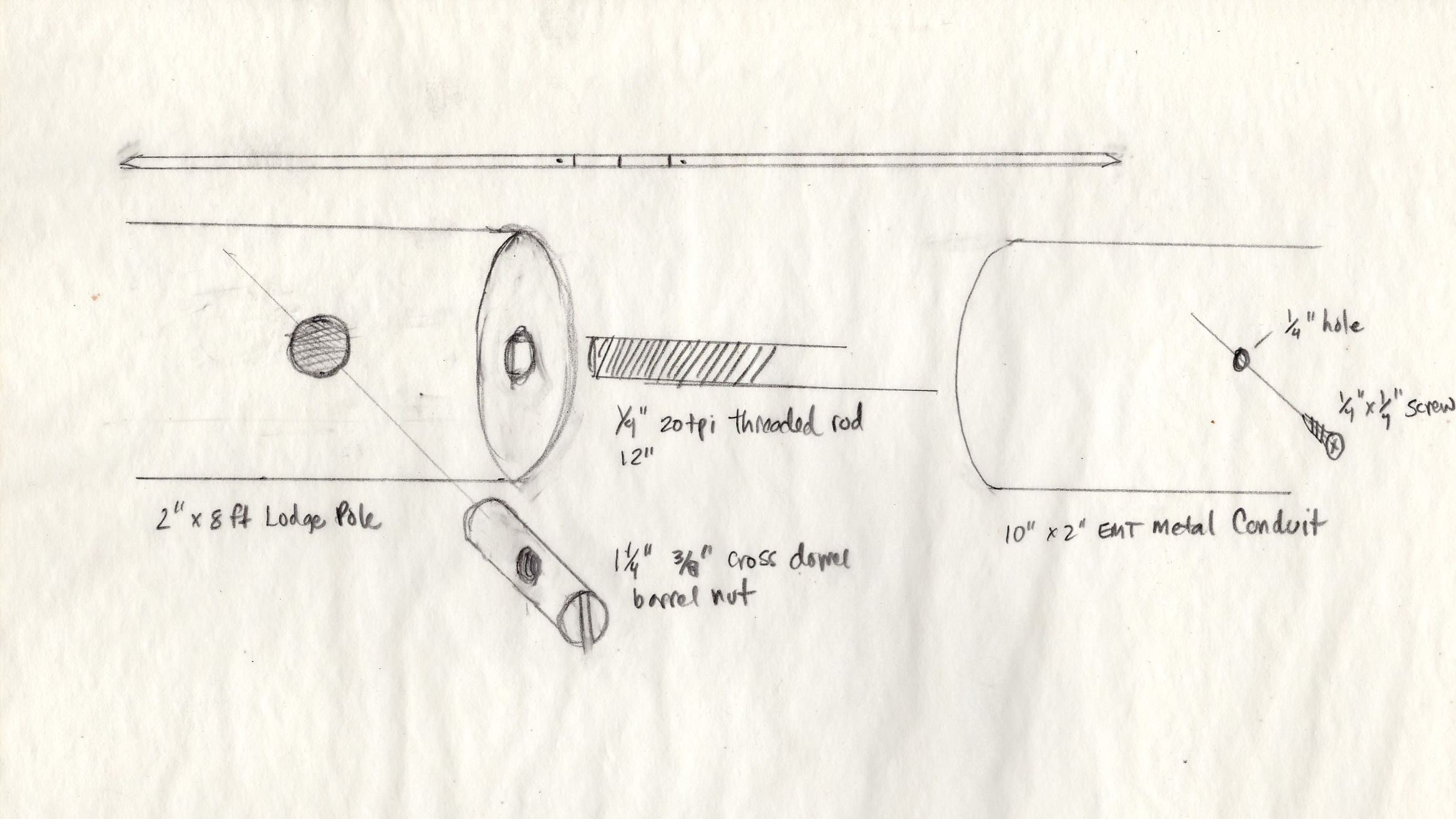

These poles also come in 8 ft. lengths, so to get to the target 16 ft. length we would have to couple these just like the bamboo. Unlike bamboo, we can’t as easily jam a 1 inch dowel through the middle, and there was a greater probability of splitting. The lodge poles also weight quite a bit more than bamboo.

The solution we came up with was inspired by flat-pack particle board IKEA furniture. IKEA often secures butt-fit MDF boards with long bolts connected to cross dowel barrel nuts sunk a ways into the board.

Because we are talking about coupling two 8ft. poles end-to-end, we are going to be using a lot bigger hardware than IKEA. For the bolt, we are using two foot length 1/2″ threaded rod. Although barrel nuts are fairly easy to find, 1/2″ barrel nuts with 13 topi thread are not. We rejected the idea of tapping out 48 pieces of metal rod, even if they were aluminum. Instead, we will drill 1/2″ holes across 1″ dowels, rebate the holes to accommodate pound a 1/2″ 4-prong t-nut. In essence, create a 1/2″ barrel nut out of the dowel. I’m hoping that a foot of threaded rod on each side of the joint will make it secure. If not, there is the option of sliding a 1 foot section of 2″ EMT across the joint on the outside, perhaps securing it in position with some 1/2″ screws.

So, it seems like we solved the structure problem for now.